Sustainability

Insights 02.01.2024

Key Considerations for Going Electric

Jackson Reid

Demetrios Stamatakis

All activities on a construction site revolve around the tower crane. Irregularities in the crane’s workload are often felt immediately—thus the need for a smooth-running hoisting schedule and logistics plan based on multiple variables. Superintendents manage crane movements through logs, schedules and time worn intuition. As schedules become more complex and activities on site produce more and more data, field supervisors need new tools to better understand the state of the project. There is great opportunity emerging in artificial intelligence [AI] to augment field supervision in monitoring the pulse of the crane’s activity.

Several months ago Versatile Natures, a startup from Tel Aviv with a presence in New York and San Francisco, invited GLY to join their Lighthouse program for early adopters. Bringing together experts from both the construction and manufacturing fields, the Lighthouse program reimagines construction projects as vertical manufacturing floors using machine learning AI for process analysis. Versatile Natures developed a device that attaches under the main hook of a tower crane and tracks everything from the precise elevation and GPS location of the crane’s hook to the weight of each load picked. All data collected is processed in the cloud and analyzed by the device’s corresponding application, CraneView™. As an early adopter, GLY began piloting this technology in August 2019 at the Overlake Medical Center Project FutureCare jobsite.

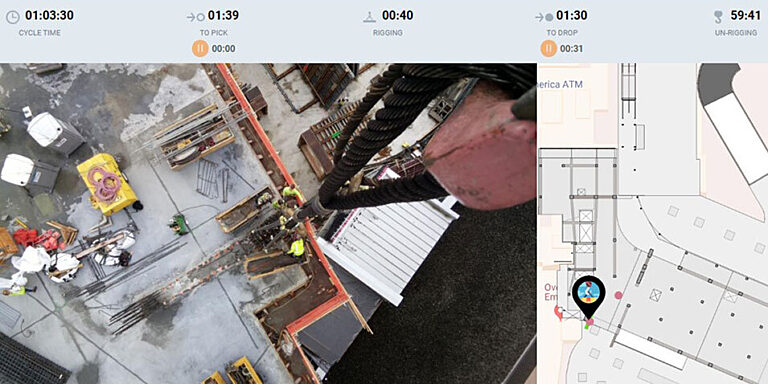

In August 2019, Versatile Natures and GLY installed the new CraneView™ tracking device to the crane hook at the Overlake Medical Center Project FutureCare jobsite.

Cameras within the device continuously record and feed images through a machine learning AI algorithm that classifies and sorts each picture. The data collected by the attachment can be viewed using Versatile Natures’ CraneView™ app on phones, tablets and PCs. This application is customizable and allows individual users to create tailored reports and visualizations. CraneView’s AI analyzes the data being streamed from the device and compares it against the 3D model of the building structure, as well as the project schedule. The comparison trains the algorithm and, over time, creates the possibility of predictive analytics to provide insights that will inform scheduling and location awareness.

This is especially powerful for high rise construction projects with repetitive floor plans where accurate data collection and comparison from previous floors can benefit delivery of subsequent floors. It also has the potential to benefit non-high-rise projects by accurately analyzing work in place and key performance indicators down to the second.

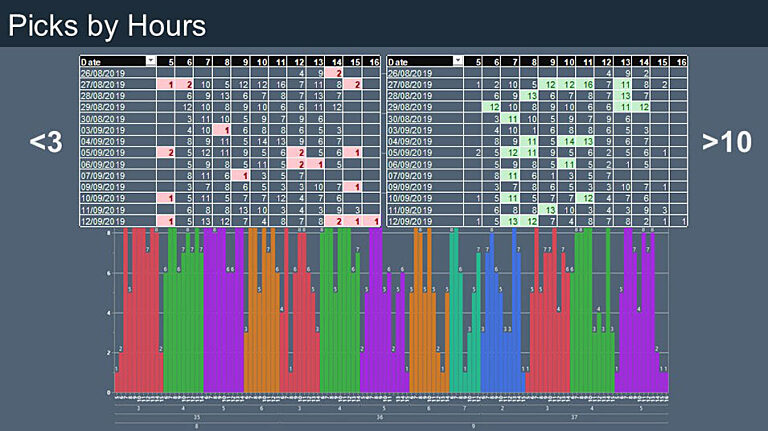

CraneView™ provides an extensive amount of data including picks by hours and load types.

GLY is using the data collected to understand current tower crane usage and to identify opportunities to optimize use and improve practices. We’re seeking to validate existing practices and/or identify inconsistencies and anomalies in ongoing work. This information will help us level out the peaks and valleys of usage, distribute activity more evenly, and ensure a safer jobsite. Identifying windows of lower crane activity will allow us to efficiently schedule site organization and other routine tasks. This accurately detailed record of crane activity is proving useful in managing subcontractors’ needs for crane time and facilitates a steady rhythm of activity on the job site helping us work towards eliminating lulls or periods of frenzied activity.

As part of the Lighthouse program pilot, GLY has been meeting bi-weekly with Versatile Natures to gain a greater understanding of how to interpret and leverage the data the technology is generating.

Perhaps CraneView’s greatest potential is its ability to facilitate difficult conversations that challenge historic best practices so that we can evolve as General Contractors and continue to deliver projects more efficiently and at a lower cost. For an industry that gets a bad rap for being change-averse, this dialog is powerful and can go a long way to modernizing construction practices.

The CraneView™ application displays the view from crane hook as well as real-time pick tracking stats.

In this age of digital transformation, with escalating material and labor costs and schedule compression becoming the norm on every project, this technology offers great promise in assisting General Contractors with efficiency gains that go straight to the bottom line. Automated data collection as part of a contemporary construction management approach helps create an accurate picture of construction progress and reveals, or at best predicts, possible issues on the spot. This is in addition to accurately recording activity metrics and key performance indicators for use in future estimation and project planning.

The promise of prediction through AI has yet to be fully realized, but during the short time we have participated in the Lighthouse program our first glimpses into an AI-assisted future give us great cause for optimism. The rise of machine learning and artificial intelligence tools like Versatile Natures’ CraneView™ point to an algorithm mediated digital transformation for the construction industry.

The industry is ready for a technology transformation, and we couldn’t be more excited to be among the first to lead the way.

Tags: